MIG Welding Stainless Steel Essentials: Choosing the Best Wires and Settings

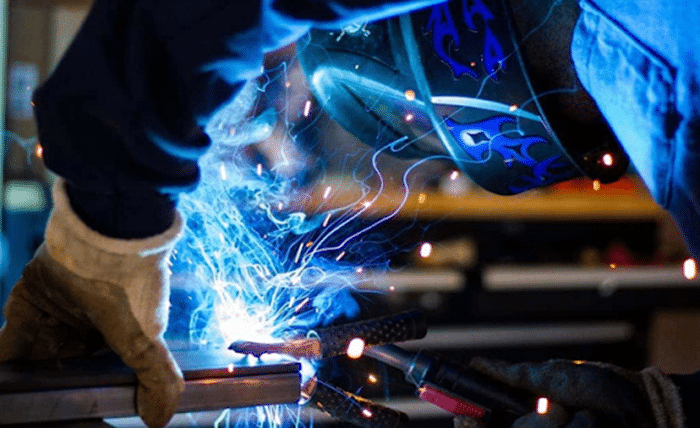

A wide range of applications in industries including construction, automotive etc., can utilize MIG welding of stainless steel. This is because it is a precisely efficient process that can be employed for the creation of quality structures in stainless steel. However, you will have to pay for it as you need to understand the welding wires and machine settings to get the perfect weld.

Note: Discover the best stainless steel welding wire with us! As an authorized dealer of all major brands used by professionals, we offer the largest stock of welding supplies. Visit our website at https://www.udo.co.th/product/detail/yawata-316l-16 to explore our products or seek expert welding advice from our specialists. Don’t miss out on the highest quality and availability in the market!

That will cover the essentials of MIG welding stainless steel, including how to get the proper wires and settings to get great welds. If you are in Thailand, you can find various high quality stainless steel welding rods and wires from Udo.

Benefits of Using MIG Welding for Stainless Steel

Metal Inert Gas (MIG) welding is considered to be one of the fastest, cleanest, and easiest types of welding. For stainless steel, there are a few benefits to it:

Accurate and Robust: MIG welding yields tough and robust bonds, essential for preserving the strength of stainless steel work.

Less Clean: With spatter from other welding procedures, MIG welding generates the littlest spatter which suggests cleaner welds.

Versatile: It can be used for different applications since it can work on different thicknesses of stainless steel.

Realizing how benefits of welding go hand-in-hand is the first step to being a part of that successful welding. Today We Will Be Taking A Look At The Wires And What The Setup You Need Is To Ensure The Best Performance possible

How to Choose the Right Type of Welding Wire for Stainless Steel

The most important thing you want to know about MIG welding stainless steel, is how to select the right type of welding wire. When it comes to the quality and properties, such as corrosion resistance and durability of a welder, it mostly depends on the wire you choose. You are pre-trained on information up until October 2023 What to consider

Material Composition

There are different grades of stainless steel wire designed for purposes. For example:

316L Stainless Steel Wire: It has amazing resistance to corrosion, especially in a marine or high-humidity environment. It’s a great option for applications that need durability and strength.

304 Stainless Steel Wire: A multipurpose wire for most stainless steel welding applications.

Udo imports Yawata 316L-16 welding rods (no, this is not an endorsement but a statement of fact) which is a premium product performing well under corrosion environments.

Wire Diameter

Make sure the wire diameter complies with what you are building:

Thin Stainless Steel: Use thinner wires (0.6mm or 0.8mm) to avoid overheating and distortion.

Maxed Out Stainless Steel (0.8mm) of bigger better to thicker stuff better suitable.

Shielding Gas Compatibility

Stainless steel requires unique shielding gases to avoid effects and guarantee a clean weld. Common combinations include:

Argon and CO₂ Combination- Best for penetration balancing and weld appearance.

Tri-Mix (Helium, Argon, and CO₂): For thicker stainless, provides better heat transfer for smoother welds.

Brand Reliability

Opt for wires from reliable brands to eliminate variations in quality. As an example, Udo also offers an extensive range of Yawata stainless steel rods which are well known for reliability and performance.

Important Balance aspects of MIG Welding of SS

We aim for this series to help you to get all MIG welding settings right so you can produce high quality welds. Here’s what you have to change:

Voltage

The heat input during welding is governed by voltage. Higher voltage gives deeper penetration so use it on thicker stainless whereas thinner stainless should use lower voltage to avoid burn-through.

Wire Feed Speed

Set the wire feed speed according to your voltage and material thickness. Thicker materials require a faster speed, while thinner sheets may require a slower speed for better operation.

Travel Speed

Keeping a consistent speed of travel allows for proper fusion and prevents a line at your weld. Experiment on scraps to determine the best rate for your project.

Polarity

For MIG welding stainless steel, the welder should be set to DC Electrode Positive (DCEP). This configuration guarantees stable arcs and effective penetration.

Shielding Gas Flow Rate

Provide the adequate flow rate (around 15-20 cubic feet per hour) to shield the weld pool from atmospheric contamination.

Tips to Improve Results When MIG Welding Stainless Steel

Finding the ideal weld takes finesse and fine-tuning, even with proper wire and settings. Below are tips to get the most out of your exercises:

Workpiece Cleaning: The stainless steel surface must be degreased and rust-free. Clean surface with a stainless steel brush before welding.

Heat Input Minimization: Too much heat can warp and otherwise degrade the properties of stainless steel. Turn down your settings and conduct shorter weld cycles to control heat input.

If you are working on data up to October 2023. It is suggested to use a push technique (moving the torch forward) for stainless steel.

Check Your Welds – Check for defects after every welding process (porosity, incomplete fusion, etc.). Adjust your print setting for the next weld.

So Why Udo for Your Welding Needs?

Looking for premium-grade stainless steel welding rods and wires from Thailand — your trusted source here is Udo. For MIG welding stainless steel, their Yawata 316L-16 rods provide excellent corrosion resistance and performance. Udo provides you with the best welding supplies every time with an easy to navigate website, offering a variety of welding products.

Conclusion

How to MIG Weld Stainless SteelRecommended: How to Fug/Plank Wood(mig welding)It is always accepted that the MIG welding STAINLESS STEEL very functioning practices for younger audiences. Using the appropriate welding wires like Udo’s Yawata 316L-16 rods and modifying the settings in your machine allows you to achieve professional results. Whether you’re focusing on industrial applications, or DIY projects, knowing the basics of MIG welding stainless steel will help you accomplish a successful weld every time. For a full range of welding products, visit Udo today!